New line of taps for stainless steels

The technology of the future is in your hands: A new line of taps developed in collaboration with a university offers cutting-edge precision and increased tool life.

The combination of industry and science brings excellent results

Our company, NAREX Ždánice, spol. s r.o., presents a new premium line of taps FeniX (catalog number NXFX), which was developed thanks to intensive cooperation with a research team at Brno University of Technology. The result is a tool that sets a new standard in threading – in terms of performance, tool life, and reliability. In numerous comparative tests, it outperformed the results of the premium taps from competitors among the world's top manufacturers.

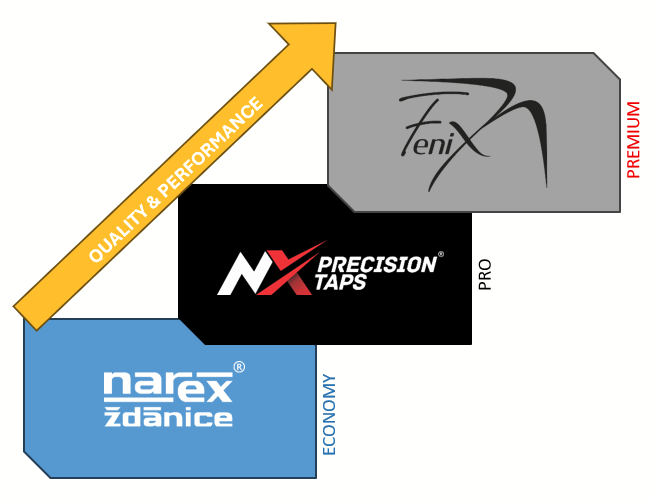

Comparison chart of our product lines:

Innovation based on data and testing

Development took place on two levels: practical manufacturing experience was combined with academic research into materials, coatings, and cutting edge geometries. Prototypes underwent dozens of test series in both laboratory and real operating conditions..

„We wanted to create a tap that could withstand even the most demanding applications in precision engineering,“ says Radek Maliha, CEO of the company. „Cooperation with the university has enabled us to take development one step further – based on measurements, simulations, and materials research.“

The result is:

✅ Taps with new geometry developed specifically for use in stainless steels

✅ Significantly extended tool life thanks to a new generation of coatings

✅ Better chip removal

✅ Thread stability even at high speeds and more aggressive settings

New TIGAAN TAPS coating

The excellent results were aided by the important fact that, in cooperation with the Šumperk-based company SHM, we developed a special coating for this new series. TIGAAN TAPS, which has taken the performance and durability of the tool to an even higher level.

Innovative multi-layer magnetron PVD coating based on AlTiN with additional ionization, which pushes the boundaries of performance and reliability of taps to a whole new level.

Total thickness 1–3 μm, microhardness of AlTiN layer 3300 HV, thermal stability up to 900 °C.

Its main advantages include reduced surface roughness, which ensures smooth threading and minimizes wear. The innovative sliding section optimizes friction properties, reduces friction, and improves chip removal.

The multi-layer structure of the AlTiN coating provides high hardness and excellent wear resistance even under demanding conditions. Additional ionization increases the adhesion of the coating and extends the tool life of the tool.

Premium line

The new line is designed not only for high-end applications, but also for customers looking for higher performance without compromising on machining stainless steels – all with an emphasis on long-term reliability. Variants with a straight flute and spiral point or a 45° helix are available..

The premium line of taps is now available in our catalog and in stock for B2B partners. If you want to be among the first to put it into production, contact our sales department.

Click to view individual products from the new Fenix range:

or download the catalog leaflet in PDF format: